Editorial: View Mate All Glass Railing

Frameless glass balustrades offer stunning, unobstructed views—the ultimate goal for modern balconies, stairs, and terraces. However, the sleek “floating glass” effect is entirely dependent on a critical element: the secure fixation of the glass. Forgetting aesthetics for a moment, it is precision engineering and safety that take precedence.

一、Safety is Non-Negotiable

Minimalist beauty requires absolute confidence in the fixing system. Each connection point bears significant load—from the weight of people leaning to wind pressure and structural movement. Compliance with stringent building codes, such as impact ratings and load requirements, is essential. The fixings are the foundation.

Core Fixing Methods: Spigots vs. Channels

Glass Clamp Spigots (Standoffs): The most common “invisible” fixings. High-grade stainless steel pins anchor into the structure (concrete, steel, timber). The glass clamps onto these spigots using precision plates and caps, typically with structural silicone for adhesion and sealing.

Critical Detail: The drilled hole in the glass must be perfect – achieved through diamond core drilling, with polished edges, and silicone buffering to prevent stress cracks. The length of the spigot and the depth of structural embedment are crucial and necessitate precise calculation

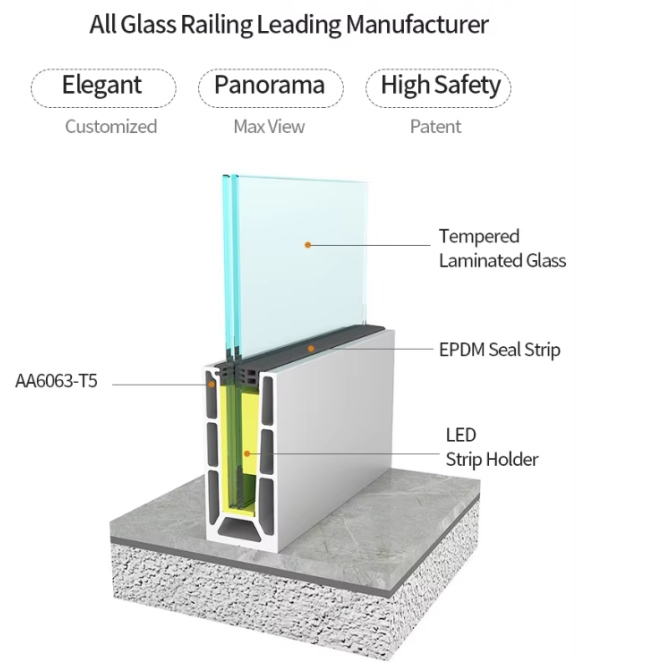

U-Channel Systems: A robust metal channel (aluminium or stainless steel) is fixed to the floor or stair.

Clamped: Metal covers mechanically clamp the glass within the channel, often supplemented with structural silicone.

Silicone Bonded (SSG): The glass is bonded directly into the channel using high-strength structural silicone, creating ultra-clean lines. This method demands expert surface preparation and application.

二、Fixing Details Make or Break Your Project

Mistakes in the details can jeopardize everything, leading to annoying flex and noise, and even failure. Conversely, getting them right ensures decades of impressive, safe performance. Key considerations include:

Substrate Compatibility: Concrete, steel, or timber? Each requires specific anchors and preparation.

Load & Spacing: These are determined by the height and thickness of the glass (e.g., ranging from 15mm to 21.5mm for toughened or laminated glass), the span, and local building codes.

Movement Accommodation: Structures are subject to movement! Fixings must allow for thermal expansion and settling without causing stress to the glass.

三、The Takeaway

Specifying frameless glass involves more than just the panels. Success is contingent upon expertly engineered fixing solutions that are tailored to your project’s unique structure, loads, and design. Partner with suppliers who offer deep technical expertise alongside the glass – because when it comes to that breathtaking, sheer drop, the invisible details truly hold everything together.

If you wish to obtain more information and explore related products, please click here to contact me.

Post time: Jun-13-2025