A40 aluminum alloy U-channel all-glass guardrail is a modern architectural guardrail system combining high-strength materials with innovative design, and its core features include the following

1. Structural design and material properties.

A40 aluminum alloy U-channel

Made of high-strength aluminum alloy profiles (A40 stands for Aluminum Model), which are lightweight, corrosion-resistant and oxidation-resistant, the U-channel design provides solid support by wrapping around the edge of the glass while simplifying the installation process. The frame is usually fixed to the building structure by expansion bolts or shot nails, with no less than 3 fixing points on each side to ensure stability.

10+10 Laminated Tempered Glass

Made of two layers of 10mm thick tempered glass bonded by PVB film, it combines high strength and safety. Its impact strength is 4-5 times higher than that of ordinary glass, and the fragments are still adhered to the laminated layer after breaking to avoid splashing and injuries. The glass thickness can be adjusted according to the demand, and the larger size (e.g. increase in height or width) can improve the overall wind pressure and load capacity, which is suitable for high-rise or large-span scenes.

2. Physical properties and load capacity.

High strength and load capacity

The double laminated structure significantly improves the bending stress and wind pressure resistance of the glass. For example, 10+10 laminated glass has a low heat transfer coefficient of 2.39 W/m²-K (double-row installation) and sound insulation of up to 38 dB, while at the same time being able to withstand higher wind loads (by calculating the adapted length through the bending modulus).

Large Size Advantage

When the length and width of the glass is increased, mechanical calculations need to be made in conjunction with the support spacing of the U-channels and the density of the fixing points of the frame. For example, additional reinforcement is required when the length of U-shaped glass installed in a single row exceeds 4m, and double-row installation can further improve the overall stability.

3. Installation process and detailing.

U-channel installation specifications

The spacing of the grooves should be consistent (usually positioned by auxiliary tape), and the depth of glass insertion is required: upper frame ≥20mm, lower frame ≥12mm, left and right side frames ≥20mm. after filling the gap with elastic cushioning strip (contact surface ≥10mm), silicone adhesive sealing is adopted to cope with thermal expansion and cold contraction.

Safety Protection Measures

The bottom of the glass needs to be padded with anti-corrosion gaskets, and the top is reserved with ≥25mm expansion joints with the building structure. The aluminum alloy frame and steel fixing parts should be equipped with synthetic material gaskets to prevent galvanic corrosion.

4. Application Scenarios and Design Criteria.

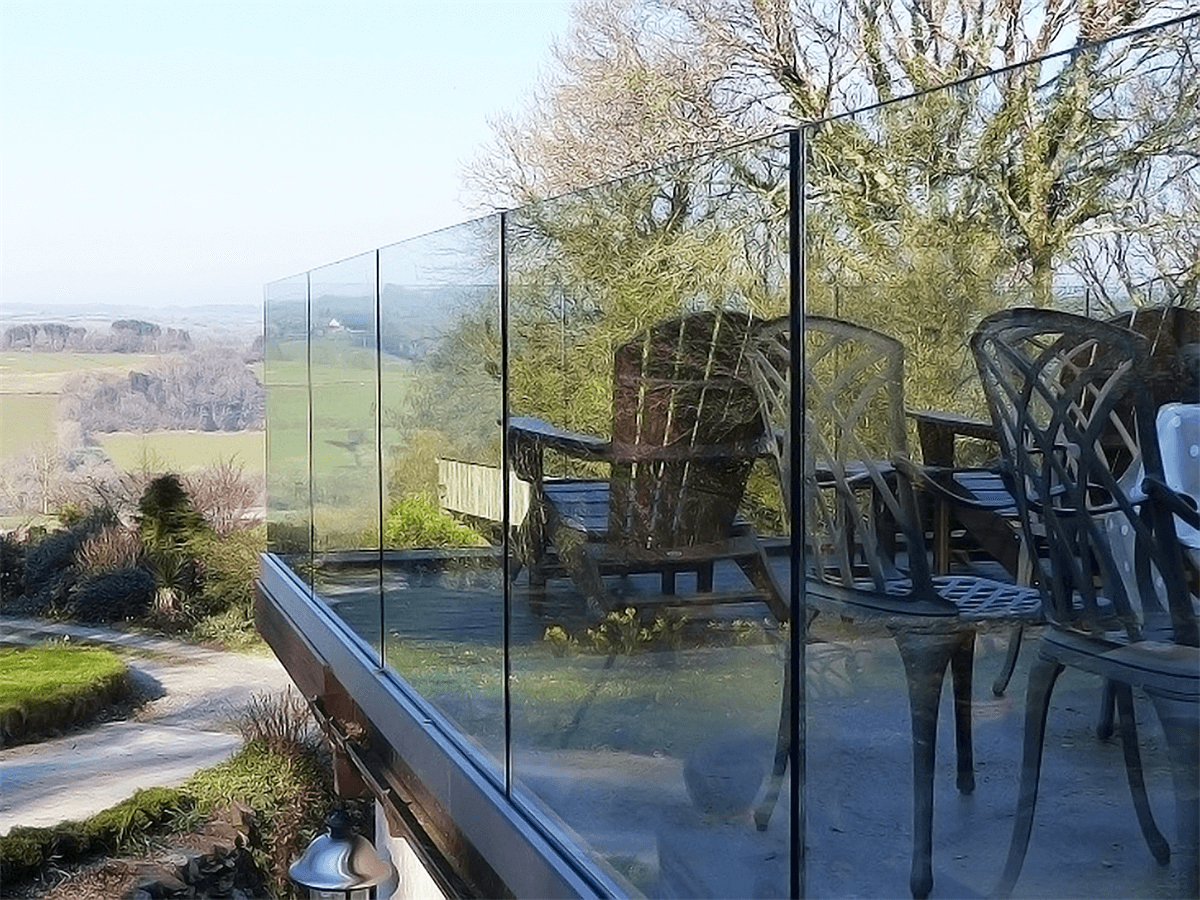

Application Scenario

Widely used in residential balconies, commercial complexes, airports, rail transportation and other areas that require high permeability and safety. The light transmittance rate can reach 81% (double-row installation), both light and privacy protection110.

Specification Requirements

The height of the guardrail should comply with the national standard (e.g. ≥1100mm from the ground), the gap between the glass and the groove ≤100mm, the thickness of the glass is recommended to be ≥12mm, and the preferred type is toughened or laminated to ensure the anti-aging property.

5. Economy and maintenance.

Comprehensive Cost Advantages

Compared with traditional metal parapets, U-channel system can reduce the construction volume by 30%-50% and save metal profiles by 20%-40%, and the maintenance cost is low, only need to check the aging condition of sealant regularly.

References.

Similar designs have been applied to projects such as Chilean Pavilion in Shanghai World Expo and Ningbo Museum, which verified its safety and aesthetic value.

Through material innovation and structural optimization, A40 aluminum alloy U-channel all-glass guardrail realizes the combination of high strength, high safety and modern aesthetics, which is especially suitable for large-size and high-load scenarios. The design needs to strictly follow the installation specifications and mechanical calculations to ensure long-term stability and compliance.

Post time: May-21-2025