Editor: View Mate All Glass Railing

Glass Types for Railings

1.Float Glass (Pilkington Process)

Manufacturing: Molten glass floated on molten tin to achieve uniform thickness.

Characteristics:

Non-tempered, basic structural properties.

Rarely used in railings without further processing.

2.Annealed Glass

Process: Slow cooling in a lehr kiln to relieve internal stresses.

Limitations:

Prone to thermal/mechanical shock.

Break Pattern: Dangerous large shards (non-compliant with safety standards)

3.Heat-Strengthened Glass

Process: Heated to 650°C, cooled moderately (2× strength of annealed).

Applications: Curtain walls where full tempering isn’t required.

Break Pattern: Larger fragments than tempered (partial safety)

4.Tempered Glass

Process: Rapid quenching at 700°C (4-5× stronger than annealed).

Safety Compliance:

Break Pattern: Granular fragments (EN 12150/CPSC 1201 certified). Mandatory for freestanding balustrades.

Risk: Spontaneous breakage due to impurities.

Solution: Heat soaking at 290°C for 2 hours to eliminate unstable NiS.

5.Glazing Systems Comparison

|

System |

Advantages | Limitations |

|

Wet Glaze |

- Superior weather resistance |

- Portland cement damages PVB |

|

(Gypsum/Silicone) |

- Ideal for curved installations |

- 24-48hr curing time |

|

Dry Glaze |

- 80% faster installation |

- Higher material cost |

| (Gasket/Clamp) | - No curing required |

- Limited to straight runs |

6.Structural Loads

Linear Load: 50 plf (0.73 kN/m)

Concentrated Load: 200 lbs (0.89 kN) at top edge.

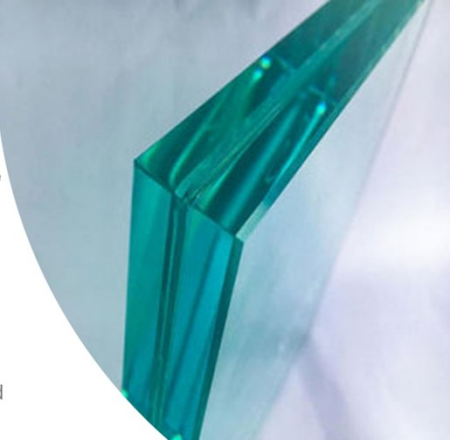

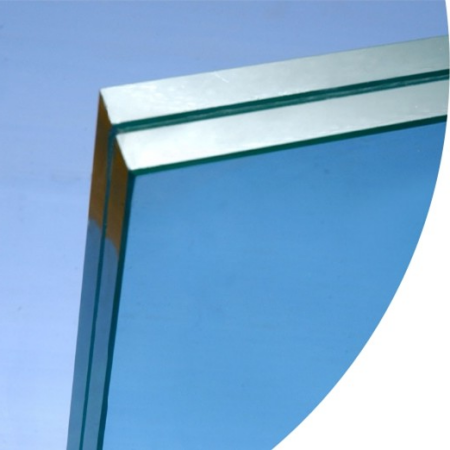

Laminated Glass Mandate

Post-2015 IBC: All railings require laminated glass (≥2 plies, equal thickness).

Exception: Monolithic tempered glass permitted only if no walking surface below

7.Top Rail Exemption

Allowed if:

Laminated glass passes load tests (ASCE 7).

Approved by local building official (2018 IBC removes this requirement).

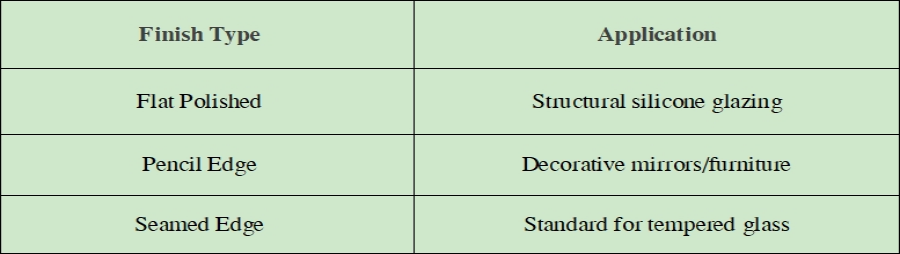

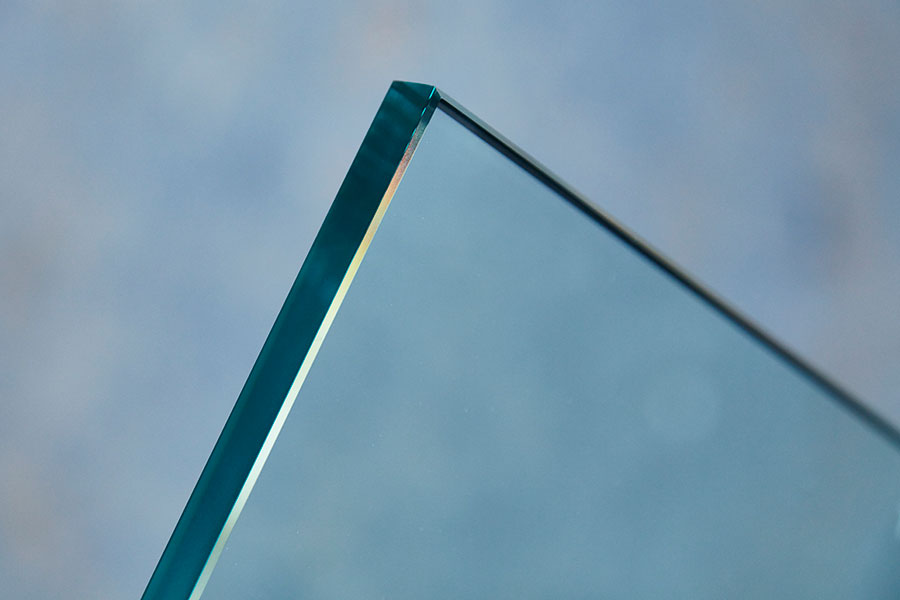

Edge Finishes & Durability

Key Concern: Ionoplast interlayers outperform PVB in humidity resistance.

8.Common Failure Modes

Nelophobia Triggers:

Nickel sulfide inclusions (heat soaking reduces risk by 95%).

Improper edge alignment (ASTM C1172 compliance critical).

9.Wind-Borne Debris Zones

Wind-borne debris regions include the Gulf of Mexico, Atlantic coastline, Hawaii • Balusters and in-fill panels shall be laminated glass • Glass supporting top rail – The assembly shall be tested according to the impact requirements – Top rail shall remain in place after impact

10.Conclusions

Railing systems designed with laminated glass provide safety and glass retention after breakage • Ionoplast interlayers are stronger, deflect less, and provide better post-glass breakage performance in minimally supported railings • Building code requirements for railings allow laminated glass and, in some cases, require laminated glass for missile impact and structural glass systems • Sealant compatibility and glazing support details require special attention

Post time: Jun-25-2025